Jigsaw Cutting Guide: How to use a jigsaw safely

If you have one power saw in your tool box, make sure it’s a jigsaw. As power tools go, it’ll be one you reach for most – next to your drill/driver. From cutting wooden boards in straight lines to creating intricate patterns in sheet metals, a good handheld jigsaw is more than able to deal with even the trickiest of cutting tasks. But are you currently getting the most out of yours?

We’ve put together the ultimate jigsaw how-to guide. Whether you want to brush up on the basic techniques or you’re looking for the real insider trade secrets – this guide is for you. It doesn’t matter if you’re a curious DIY novice or seasoned pro. We’ve taken all the most useful information on jigsaw uses, features and benefits – and brought it here into one place.

If you use the tips and tricks in this guide, your projects will be a sight for saw eyes in no time!

What is a jigsaw?

An ever-popular power tool from the SGS product range, a jigsaw is a saw that can be used to cut irregular curves in wood, metal and other materials. When working with a jigsaw, its blade makes the cut in a ‘push-and-pull’ motion. This is otherwise known as “reciprocating” blade.

Curved or angled – the cuts you can achieve with a jigsaw tool make any projects quicker and easier to complete. And it’s important to know how to operate a jigsaw to maximum effect. In doing so, you can be sure of superb cutting results – and reflect on a job that’s truly well done.

It’s just one reason that we’ve produced this comprehensive jigsaw cutting guide.

How to choose your jigsaw

To start, let us help make sure you choose the right handheld jigsaw from our extensive range of products. With options from some of the most renowned power tool brands, it’s easy to find the one that’s right for you. See some of our most popular portable jigsaws below:

Ryobi ONE+ R18JS-0 18V Cordless Jigsaw with Flush Cut & LED Light

This 18V Ryobi ONE+ jigsaw is a top-of-class cordless power tool – combining the performance, power and reliability you’d expect from a corded option. It offers up to 3,000 SPM and features a 4-stage pendulum stabilisation to achieve the perfect cut every time.

With the freedom and convenience this battery-powered jigsaw provides, it’s the ideal addition to any shed, workshop or garage. With long-lasting run time thanks to the Ryobi ONE+ battery, there’s no need for any trailing cables or nearby power sockets when you need to get the job done.

Makita DJV182Z 18V Brushless Jigsaw

More energy, more power – Makita’s DJV182Z jigsaw machine comes with an innovative motor system that automatically slows the blade speed when no load is detected. It provides you with the benefit of being able to easily trace your cutting line for improved precision.

With its brushless motor, you can expect up to 50% more runtime and 3,500 strokes a minute at its highest, no-load speed. Just in case you can’t see clearly when working with your jigsaw, the DJV182Z has twin LED work lights and built-in blower to see where you’re cutting.

Milwaukee M18BJS-0 18V Compact Jigsaw

With a 3-year warranty as standard, we’re certain that you’ll find the Milwaukee M18BJS-0 will be everything you need in a portable jigsaw. The 5-position orbital setting gives you the choice of speed and cut – whether you’re using the jigsaw to cut metal, wood or something else.

This product is designed with your convenience in mind. Blade changing is quick and easy with the QUICK-LOK™ Blade Clamp. Other features include its tool free shoe bevel with positive stops and a non-marring shoe to protect against damage. No matter the job, this option is up to it.

Still not sure how to pick a jigsaw that’s right for you? Check out our jigsaw buying guide now.

Get to Know Your Jigsaw

Before we get started with any cutting or woodworking projects, it’s a good idea to take a look at your jigsaw tool. Explore what features yours actually has and how you can adjust them. As you’ll no doubt see when you come to pick your new jigsaw, they’re not all the same. You may find that yours doesn’t have advanced features such as orbital action or a bevel adjustment.

Here are some of the features that a jigsaw can include:

Variable speed dial - Many options have several speed settings for cutting different jigsaw materials. When using a jigsaw to cut metal, for example, use a lower blade speed to keep your blades in top shape. You might also choose a slower speed setting when working with plastics. This will reduce the risk of melting your workpiece.

Orbital action - Some jigsaw saws are capable of orbital action, which means it will provide thrust to the blade as it moves up and down. These tools have an impressive cutting speed when compared to a conventional saw. If yours has this feature, use its orbital action knob to increase or decrease the jigsaw’s “thrust”.

Bevel Adjustment - Some jigsaws will have a special pivoting baseplate and bevel adjustment setting, so you can cut wood or other materials at angles. Although you probably won't use this feature day-to-day, a jigsaw with bevel function can be incredibly useful for sawing at an angle of up to around 45°.

Trigger & Lock-on switch - Your trigger starts and stops your jigsaw power tool. It might take a moment for it to get up to speed after pressing the trigger, however. So, make sure you're at capacity before your start any cut. If it has a lock-on switch, this will help you when working on a longer cut. As you hold your trigger, click this mode and you can lock a jigsaw while it continues to work.

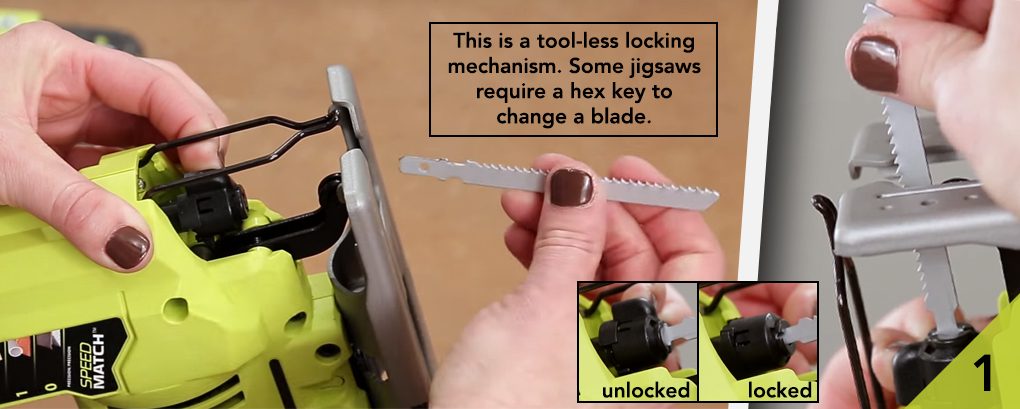

Blade & Blade clamp - A jigsaw can come with a range of locking mechanisms that secure or let you change out your blade. The simplest blade-changing systems will be toolless. But many will use a standard hex key for securing your blade in place.

How to stay safe when working with your jigsaw

Like all power tools, your safety is paramount. That’s why our jigsaw cutting guide offers some helpful tips on how to use a jigsaw in a way that keeps everyone safe:

- Jigsaws make dust. There might be a lot of it too – depending on what you’re cutting. Use a mask and goggles to keep yourself protected if working with a jigsaw.

- Using a corded jigsaw? Be sure where your power cord is. Keep it clear from your cut line. Make sure you use an extension lead that’s long enough to let you move around – but isn’t so long that you’ll get tangled up.

- A jigsaw’s blade is fairly exposed. So, keep all your appendages away from the business end. Make sure the jigsaw power tool is completely unplugged (or the battery removed) before you try to adjust a blade.

- Make sure your saw blade is sharp and fit for purpose. Old blades can go brittle and may snap during use of a jigsaw machine – causing danger to you and your workpiece.

How to Choose a Jigsaw Blade

The most common mistake when working with a jigsaw is choosing the wrong blade for the job at hand. Your jigsaw is likely to be capable of cutting anything from plywood board to sheet steel. If you pick the wrong blade, however, you’re not going to get the finish that your work deserves.

A good jigsaw blade is precision engineered for a specific task. So, to get the most out of your tool, it’s a good idea to have a range of different blades at hand. Our jigsaw guide should give you an extra edge when it comes to choosing the perfect blade:

- Shank type - Remember, not every blade will fit a jigsaw! Double check the shank type before you buy a load of brand new blades. Ryobi jigsaw blade holders, for example, will take a “T-shank blade”. “U-shank” blades are very common too.

- Amount and size of teeth - As with any cutting blade, larger teeth mean a quicker cut – but a rougher finish. Using smaller teeth, you’ll get through the jigsaw material slower. It does mean, however, that you’ll get a far finer finish. The number of teeth on a blade is measured in either “T” – meaning total teeth – or “TPI”, which is teeth per inch.

(Use fewer, larger teeth for quicker, rougher cuts or use numerous, smaller teeth for a slower, finer finish) - Narrow blades vs Wide Blades - Wider blades are best for making longer, straighter cuts. The alternative options are narrow-bladed and used for cutting curves. You should have at least three or four teeth touching the workpiece at all times during your cuts.

- Application-specific blades - Many blades are made specifically for harder or softer woods, as well as plastics or metals. The teeth shape and the blade material itself are just two factors to consider based on what you need it to cut through.

How to use a jigsaw to make a cut

We’ve seen where everything is on a jigsaw, how to stay safe when using your jigsaw and how to select the perfect blade for the project you have in mind. Now it’s time to actually use it! We have created this jigsaw how-to guide to be pretty universal. So, it should be helpful regardless of what material you're cutting or how intricate your design is.

Like anything, practice makes perfect. If you don't get it right on the first attempt, don't worry! And don’t forget that you can always finish off an untidy edge with some sandpaper and a file if the end result is a little rougher than you hoped for. Let’s get started:

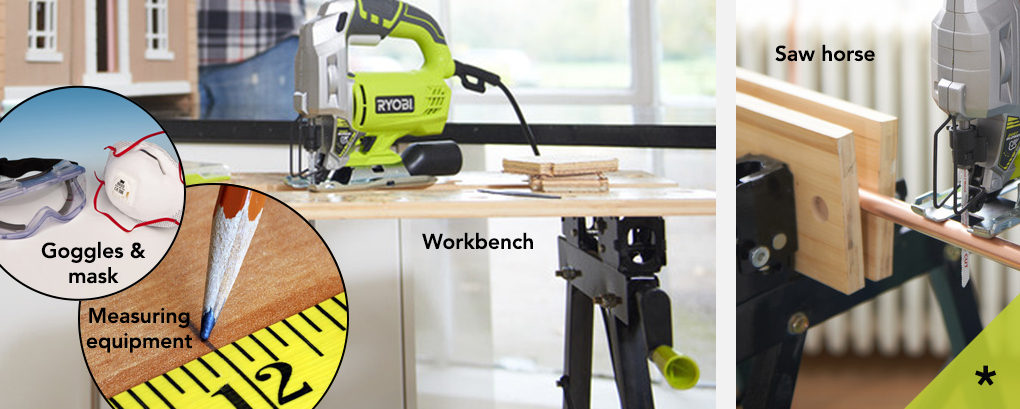

How to operate a jigsaw: What you'll need:

- Your jigsaw

- The right jigsaw blade

- Safety gear: goggles and mask

- Saw horse, workbench or similar

- Saw horse, workbench or similar

- Some clamps

- A clear workspace

- Measuring tools: tape measure, pencil, templates, etc.

1. Mount the correct blade

After choosing an appropriate blade, mount it in your jigsaw while it’s unplugged (or the battery is removed). Release the blade clamp, holding your blade in place. Secure your blade and check that it doesn’t move in the clamp. Check your jigsaw instructions for more details if needs be.

2. Prepare your workpiece

Measure and mark out your cut line on the workpiece. If you’re cutting out a hole for a specific item like a sink or an electrical socket, you might want to draw round the object itself.

For other shapes, it might be an idea to make a template first and draw round that. The more accurate your cut line is, the better chance you have of making the perfect cut.

Secure your material to a worktable or sawhorse too – using a couple of clamps to reduce any possible movement while working with a jigsaw. This will leave you with two hands to navigate your jigsaw machine around the cut line.

3. Set your saw's cutting settings

If you’re using a jigsaw that has orbital adjustments and speed settings, now’s the time to set them. Remember – an orbital action and speed setting will lead to a faster and easier cut.

Using jigsaw to cut metals or ceramics? You’ll want the lower the speed and orbital action settings. For wood, choose higher settings. You can always refine with sandpaper later.

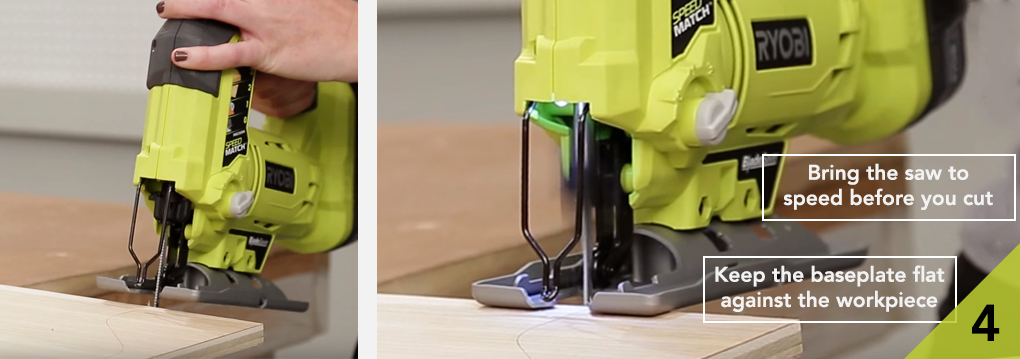

4. Lining up and getting to speed

Rest the base plate in a secure position. Slowly pull down the trigger and wait a moment for the jigsaw to get up to full speed. The base plate should stay flat throughout the cut.

5. Follow the cut line

Now you’re up to speed, push your jigsaw firmly – but slowly – into your workpiece. Guide your jigsaw blade around its path by gradually twisting the back of your saw in the opposite direction to the one you want the blade to travel.

You’ll know if you’re pushing too hard because the saw will feel as if it’s straining. You may also feel a slight kickback. Slow your forward momentum down if this is the case. Moving too fast is a sure-fire way to damage your saw blade, miss your cut line and/or splinter the workpiece.

TOP TIP: If you're cutting in a straight line, you might find it useful to clamp a guide piece of wood to your workpiece. This is normally a simple length of straight wood clamped parallel to your cut line. The base plate can rest against this as you cut. You can see an example of a jigsaw guide-piece in use above.

6. Complete your cut

Complete the cut by following your cut line to completion. Take care to make sure any excess jigsaw material can freely fall away from the workpiece without hitting you or the power cord.

Letting excess material drop off before you’ve completed a cut, however, causes the blade to bind – and possibly splinter the workpiece. With your finished piece, you can cap it off with a piece of sandpaper to get rid of some of any remaining rougher edges.

How to operate a jigsaw: Top tips and trade secrets

Now we have the basics covered in this jigsaw how-to guide. If you want some real trade-rated secrets, however, read on. The jigsaw is a power tool you can pick up and use almost instantly. And these more advanced tips will have you tackling bigger and more complicated DIY tasks in no time at all.

Starter holes

Not starting at the edge of a material? No problem. Drill yourself a starter hole roughly 5-8mm larger than your jigsaw blade. This means you can start in the centre of a workpiece, such as a countertop or a flooring board. There’s no need for difficult plunge cuts with this method!

Protect laminated or highly finished materials

By using masking tape on top of a laminated surface, you can reduce the risk of damaging the protective top layer. Special down-cutting laminate blades are available for added protection.

Know when to turn the speed down

A jigsaw’s variable speed settings aren’t just there for show. They have an important function. Slow the speed down when you’re using a jigsaw to cut metal. Your cut might take a little longer – but your blade will stay in better condition. It’s often worth bringing your cutting speed down for this sort of task. It’s slow work but it’s how you get the perfect finish.

Clamp metals between scrap wood

Clamp sheet metal between two pieces of plywood when you’re working on intricate designs or when the finish really counts. This reduces the risk of you shredding your workpiece as you cut.

Tight corners and curves

If you’re working on a corner or curve that’s too sharp to move the blade, keep backing up and restarting your cut at ever increasing angles. This will create a progressively larger kerf for your blade to turn into.

Super smooth cutting

A jigsaw cuts on the upward stroke. That’s why splintering is not unusual. If you really want to make sure you’re getting the best possible finish, use a slower blade with more teeth or buy a specialist downward cutting blade.

Choose the right blade!

We might be repeating ourselves – but we can’t say it enough. Use an appropriate blade for the material and task at hand. If you skipped our “How to choose a jigsaw blade” section, please go back and have a quick read. It’s so important to know how to use a jigsaw more effectively.

Still Need help?

Our in-house experts are always on hand to help you make the most of your new power tools – and how best to use a new jigsaw. If you have any questions or need any further advice about which corded or portable jigsaw is right for you, get in touch today.

Call SGS on 01332 576 850 or fill out our contact form.

Milwaukee Authorised Distributor

Milwaukee Authorised Distributor  4.4 out of 5 with 50,000+ reviews

4.4 out of 5 with 50,000+ reviews  Free delivery on orders over £75*

Free delivery on orders over £75*  Next working day delivery available*

Next working day delivery available*