Angle Grinder Uses: how to use an angle grinder for cutting | SGS

How to use an angle grinder safely

An angle grinder has many uses and if you know how to get the most out of it, it can be one of the most versatile tools in your toolbox. From grinding, cutting and removing excess materials, to sharpening, sanding and polishing, your angle grinder is equipped to tackle many DIY and home maintenance tasks.

There are different types of angle grinder available and we have a full range for you to choose from here at SGS Engineering. If you’re trying to find one that’s the perfect fit, we’ve created a guide to help you understand how to use a grinder, how to operate one safely and some top tips to help you choose the right one for the job.

What is an angle grinder?

Before we can look at how to use a grinding machine safely and the different angle grinder uses, it’s worth understanding what it is as this gives you an idea of when it’s needed.

A grinder is a handheld power tool that comes in different sizes and includes a range of settings. Whichever model you use, they all perform the same standard functions: grinding, cutting and polishing materials. The main materials that it can be used on are metal, tile, stone and concrete.

Most grinders are powered by electricity and you can choose between a corded or battery-powered model. The disc (also known as a wheel or blade) is the part of the tool that does the cutting, grinding or polishing and can be replaced when it’s worn.

Get to know your angle grinder

It’s helpful to know the setup before you buy your grinder, particularly if you’re new to using one of these tools. Whether you’re cutting concrete or metal with your angle grinder, if it’s the first time you’re using it, you’ll want to feel comfortable, and knowing what to expect and where to find everything will help you do just that.

Here’s a look at what a typical angle grinder looks like. You’ll see that the standard functions and features are labelled up. These details can be found on every type of angle grinder on the market.

Angle grinder uses: choosing the best angle grinder for the job

So, what is an angle grinder used for? Knowing what grinder does what will help you choose the best grinder for the task you’re working on. As mentioned previously, the three main functions of a grinder are to cut, grind or polish a material. As this is a handheld tool, it offers precision as you can move the grinder to where you need it to be.

Some of the top uses for an angle grinder include:

- Cutting ceramic tiles

- Cutting stone

- Cutting metal

- Removing paint

- Removing rust

- Removing mortar

- Cleaning metal

- Cutting and carving wood

- Planing tools

The job you’re doing will lead your decision about the type of grinder you choose. If you’re working on a large surface area − mortar, for example, you’ll need a larger wheel to match the task. It’s worth noting that if the wheel is larger, it will need more power to operate it.

For these larger tasks, a grinder like this Milwaukee 228mm version, which comes with a full kit, can be the ideal tool. Its 18v power and the substantial wheel diameter suits tougher materials.

Similarly, if you’re working on a smaller area and you need to be precise, you’ll need a smaller wheel to work around the metal or tile that you’re cutting. This Ryobi model is a cordless option and comes with a 125mm cutting disc, allowing you to move around finer materials and make precision cuts.

So, successfully cutting metal, concrete, or other materials with an angle grinder can be easy if you find the right tool. To help you choose, check out our buying guide where you can discover a comprehensive breakdown of our range.

You can also swap out the wheel for an alternative that better suits the job you’re working on. Read on to find out more about the different wheels that you could use and when to use them.

The difference between an angle grinder and a polisher

It’s worth noting here the main difference between an angle grinder and a polisher because both tools can polish materials. However, an angle grinder has more force behind it than a polisher, which means it’s more suited to heavy-duty polishing. A polisher, on the other hand, is ideal for finer, more detailed buffing and polishing work.

Angle grinder safety

Now that you’ve selected the right tool for the job, you’ll need to know how to use an angle grinder safely. Unlike a drill that will rotate at around 700 to 1,200 times per minute, an angle grinder has a free speed of up to 12,000 revolutions per minute (rpm), so it’s really important to follow some basic precautions.

Here, we’ll take you through the different steps to make sure you’re safe when using an angle grinder.

Preparing your workspace and staying safe

- Clear the area – there’s going to be dust! Move anything you don’t want to get covered out of the way before you start cutting.

- Unplug (or take the battery out of) your grinder when you’re changing the disc/wheel.

- Make sure the handles are firmly attached to the grinder.

- Always keep a firm grip of the grinder.

- If your grinder has a guard, use it.

- When you buy a new disc, run it in the grinder for at least 30 seconds to ensure you don’t have a defective blade. Be sure to do this in a safe space.

- Let debris fall downwards and out of the way of you and the grinder.

- Make sure the blade is always spinning away from you.

- Beware of sparks catching on anything combustible in your workspace.

- Keep work pieces clamped or secured wherever possible.

An angle grinder produces a large amount of dust and sparks, so you need to be well prepared before you start your project. Keep your working area clear of obstacles and make sure there’s nothing that could catch fire with a stray spark.

When you’re working with an angle grinder, we suggest you wear goggles, tough gloves, protective boots and a dust mask. Cutting masonry and some tiles will make a large amount of dust, so a dust mask is essential when working on these projects. Bear in mind a spark could burn you or catch against your clothes, so avoid wearing flammable materials where possible.

How to use a grinding machine

Whether you’re using an angle grinder to cut stone, metal or tiles, it’s good to have an idea of how the different materials interact with this power tool. To help you get the most out of your grinder, we've put together some how-to guides.

With these simple step-by-step instructions, you’ll soon be able to cut, clean and grind with your tool.

Cutting concrete, tile and stone with an angle grinder

So, you have a tile cutter. But can you cut a tile with an angle grinder?

Tile cutters are great for cutting straight across the face of a ceramic or stone tile, however it’s difficult, if not impossible, to make precise cuts for fitting a work piece around obstacles such as power outlets. You’ll find that both going around these obstacles and cutting tiles straight is easy with an angle grinder.

The following instructions also apply to concrete and stone.

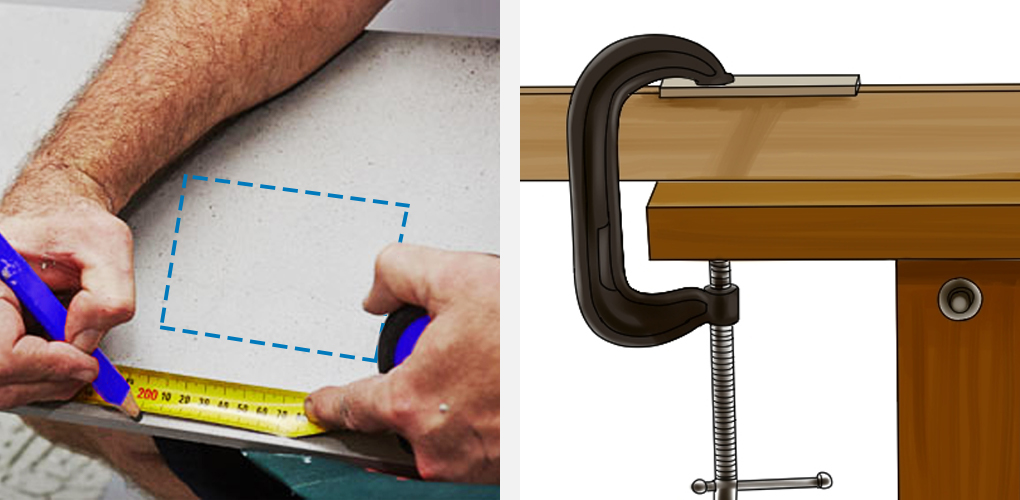

1. Marking up & clamp down

Mark an outline for the cut on both the front and back of the tile. Be as accurate as you can with the outline because the more fastidious you are now, the better a finish you’ll get.

Next, firmly clamp your tile to a workbench, with the front facing up. You risk ruining your ceramic or stone tile or potentially causing yourself an injury if it slips as you make the cut, so make sure it’s secure.

2. Scoring the face

Start your angle grinder and score around your outline on the front face of the tile. You’re aiming to score around one-eighth of the way through the surface.

3. Finish the cut

Flip your tile over and re-clamp it. Now the back of the tile should be facing up. Cut through the tile from the back. Extend your cuts slightly past the corners to get a perfect, crisp square corner.

How to cut metal bars, rods and bolts

When your choice is to either slowly and painstakingly cut away with a hacksaw, blunting numerous blades as you go – or quickly rough cut a metal bar with an angle grinder cutting machine, it makes sense to opt for the grinder. You can’t beat a grinder when it comes to convenience and saving time.

1. Prop the bar

Skip to step two if you’re trimming a bolt flush in concrete or another material. If you’re not, you’ll need to firmly prop the long side of the bar, making sure it’s secure. The shortest part of the bar (after the cut) should be the bit that drops away. Remember to wear your safety boots before you start this process to protect your feet if anything falls.

2. Making the cut

Turn your angle grinder on and allow the disc to reach a high speed. Drop the wheel through the metal, allowing the weight of the tool to do the majority of the work. Allow the short end to drop away from the bar or rod freely.

How to restore cutting edges and sharpen blades with an angle grinder

Among the top uses for your angle grinder, sharpening blades is one of the most practical. With the right disc, your angle grinder can be used to restore rough edges on many of your household tools including lawn mower blades, shovels, hoes and even axes. You can always refine the finish with a mill file afterwards.

1. Clamp your blade

Using either a vice or a c-clamp, firmly clamp down your chosen tool or blade to your workbench. An arrow on the body of the grinder will indicate which way the blade will spin so check this before you begin. By doing this, you can make sure the grinder disc will be spinning away from you, deflecting any sparks.

2. Align disc

Angle the grinder disc with the cutting edge of the blade or tool you’re working on. Start the grinder and let the disc spin at full speed. Move the disc steadily across the blade, applying only the lightest pressure.

Move the grinder from the handle end of the blade and up to the tip of the tool. Don’t move the grinder back and forth. Start at the bottom, move up to the tip of the tool, and repeat.

TOP TIP: Sharpening metal causes a lot of heat to build up. Keep a bucket of water and a sponge close by so you can cool the blade between strokes.

How to clean metal with your angle grinder

If you have the right disc, an angle grinder will make light work of removing flaking paint, dry cement or rust from metals. There are numerous wire brush-style wheels on the market, all designed for different types of stripping, cleaning and de-burring tasks. Check the manufacturer’s description before you buy.

1. Secure your work piece

Before you use your angle grinder, clamp down whatever you’re working on in a vice or on a workshop bench. Make sure the disc is going to be spinning away from you as wire brushes can catch and kick back. You can check the arrow on the angle grinder to see which way the disc will rotate.

2. Removing materials

Bring the grinder up to speed and gently move the wheel down onto the paint, rust or cement you’re trying to remove. Be sure to work away from, not into, sharp or rough edges. Wire wheels are very malleable, so you’ll be able to get in all the crevices and tight areas.

How to cut out mortar with your angel grinder

If you’ve got a lot of mortar to remove and you’re finding that a hammer and chisel just won’t cut it, get your angle grinder out instead. This is another of the top angle grinder uses. However, you need to prepare for a lot of dust when doing this job. Get yourself a dust mask, close all your windows, and warn the neighbours!

Grinding mortar

With your dust mask on, bring your grinder up to speed. Clear the joint by making two or three 12mm cuts, all in the same direction, in the mortar. Stay a couple of millimetres away from the brick work to avoid the possibility of damage.

What else can you do with an angle grinder

An angle grinder is intended for working with various materials to achieve an array of finishes and effects. By picking the right cutting wheel, you can accomplish an even larger variety of household DIY tasks including polishing, buffering, sanding, rounding and shaping. Here’s a handy table to show you the right angle grinder wheels for metal, concrete and a host of other materials and jobs.

| Type of Wheel | Recommended for |

| Aluminium Oxide | Woodworking projects |

| Buffing Pad | Buffing and polishing |

| Cut-off | Cutting metal bolts, rods, and bars |

| Diamond | Cutting concrete, stone and tiles |

| Fibre | Removing rust and burrs from metal |

| Grinding | Restoring edges and sharpening tools |

| Sanding (available with various abrasions) | Sanding, sharpening, surface prepping |

| Tuck pointing | Removing mortar |

| Wire or Brush | Cleaning metal; removing paint and rust |

Angle grinder wheels and discs can be crafted from a number of materials. However, in general, a diamond disc will allow for the greatest degree of precision and polish. Wheels are available in a range of abrasion levels (or grit). Use an accessory with a higher abrasion for rougher polishing surfaces.

Get in touch

Now that you know how to use a grinder and some of the different operations your power tool is equipped for, you’re well placed to safely and accurately grind, cut and sharpen. If you have any questions about the angle grinders we have available here at SGS Engineering why not give us a call on 01332 576 850 or fill out our contact form today. Our in-house experts are always on hand to offer buying advice and provide bespoke care, regardless of the application.

Milwaukee Authorised Distributor

Milwaukee Authorised Distributor  4.4 out of 5 with 50,000+ reviews

4.4 out of 5 with 50,000+ reviews  Free delivery on orders over £75*

Free delivery on orders over £75*  Next working day delivery available*

Next working day delivery available*